The world's largest aluminum rolling mill is run by Alcoa/Arconic in Davenport, Iowa. It is a massive plant, over a mile long, where 20 ton ingots are rolled into strips 18 feet wide and hundreds of feet long. From these, the one-piece wing planks of the world's largest aircraft are machined. Every Boeing 777, every AirBus 380 has wings from DavenportWorks, it's the only place with the capability. Virtually every Western-made commercial and military aircraft has skin and structural components made from the plant's metal.

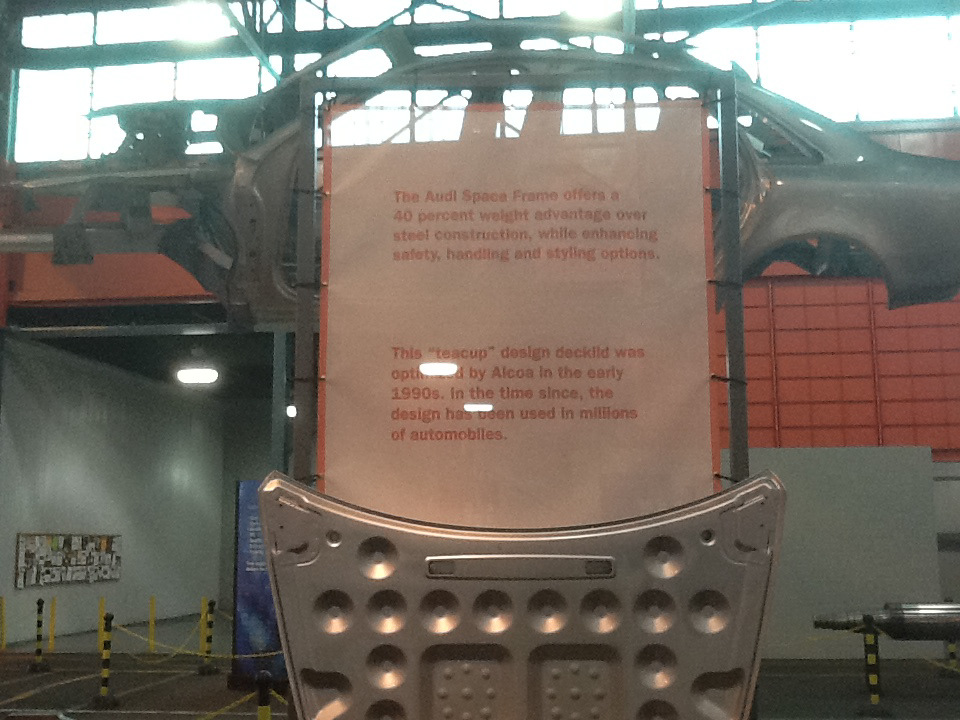

On the road, Chevrolet, Ferrari, Ford, Nissan, Porsche and Tesla, among others, use DavenportWorks-made sheet metal. Soldiers, sailors and marines owe their lives to armor made from Davenport. Thousands of consumer products have DPW inside, from Apple computers to SpaceX rockets.

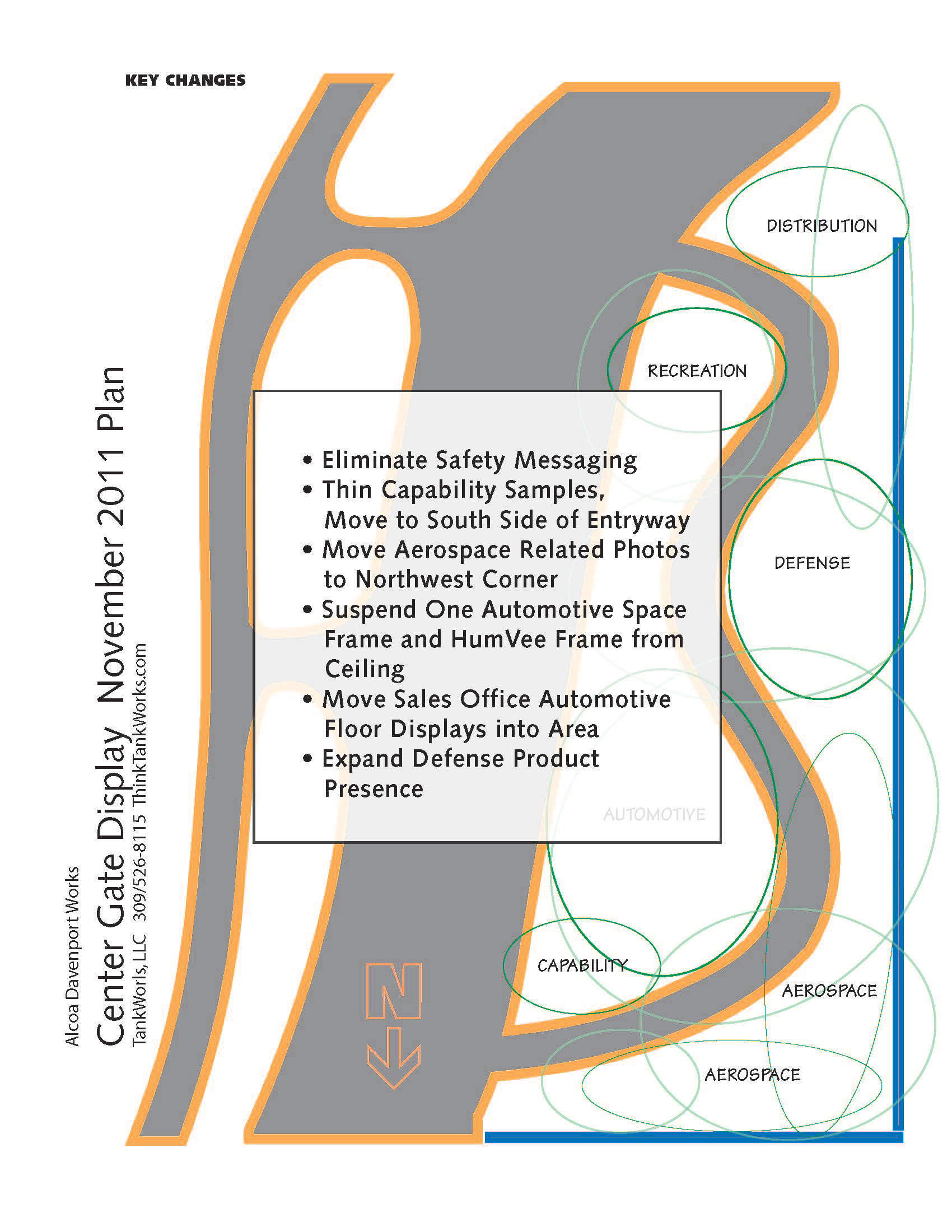

In 1993 I was given a unique challenge; the plant's marketing manager, Tim Wilkinson (RIP) pointed to a 5,000 square foot area near the plant's main entry. "When our customers come here, we give them a cart tour through the plant and this is the starting point. They're interested in the tour, but they are really coming here to negotiate. By the time they see this display and finish the tour, I want them to be questioning whether their order is worthy to be here."

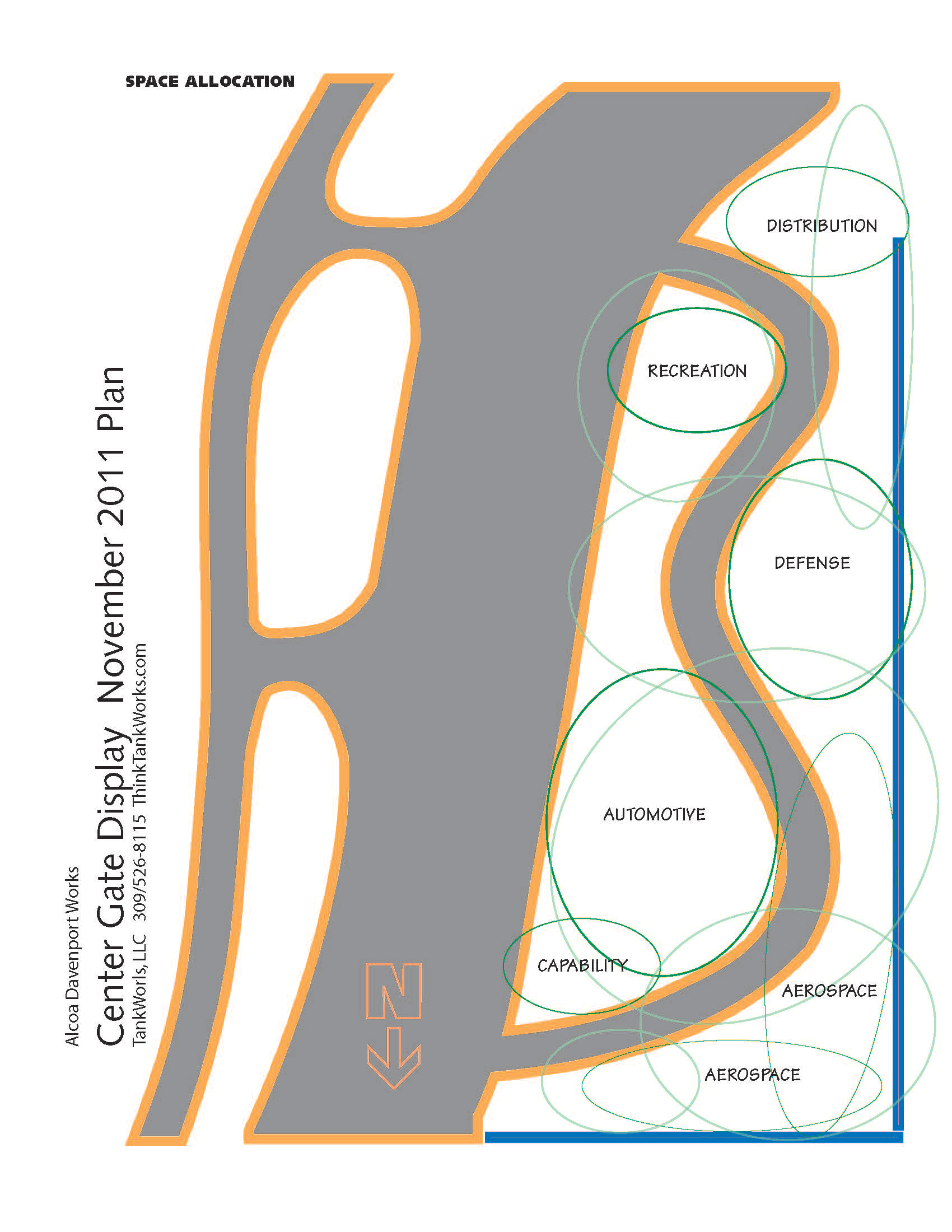

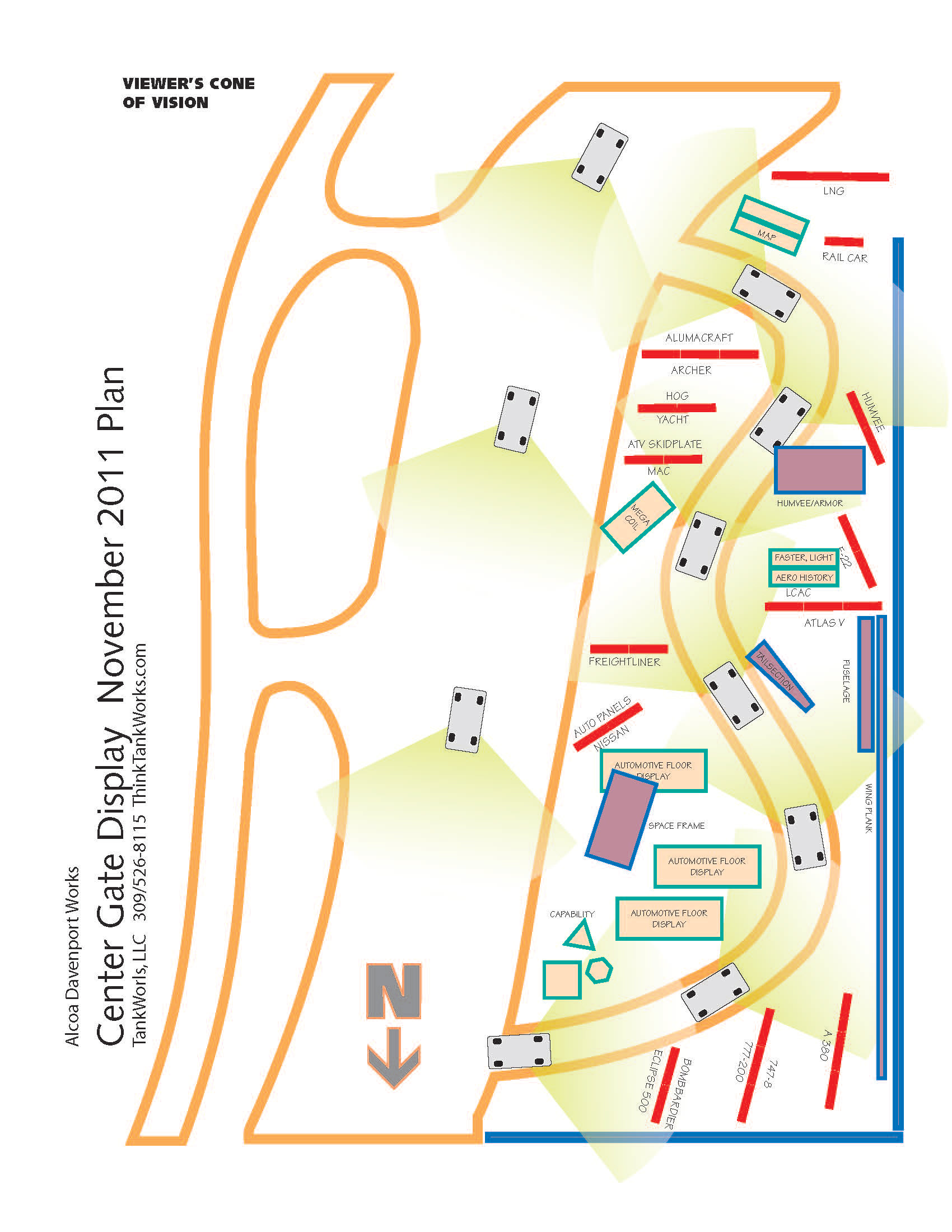

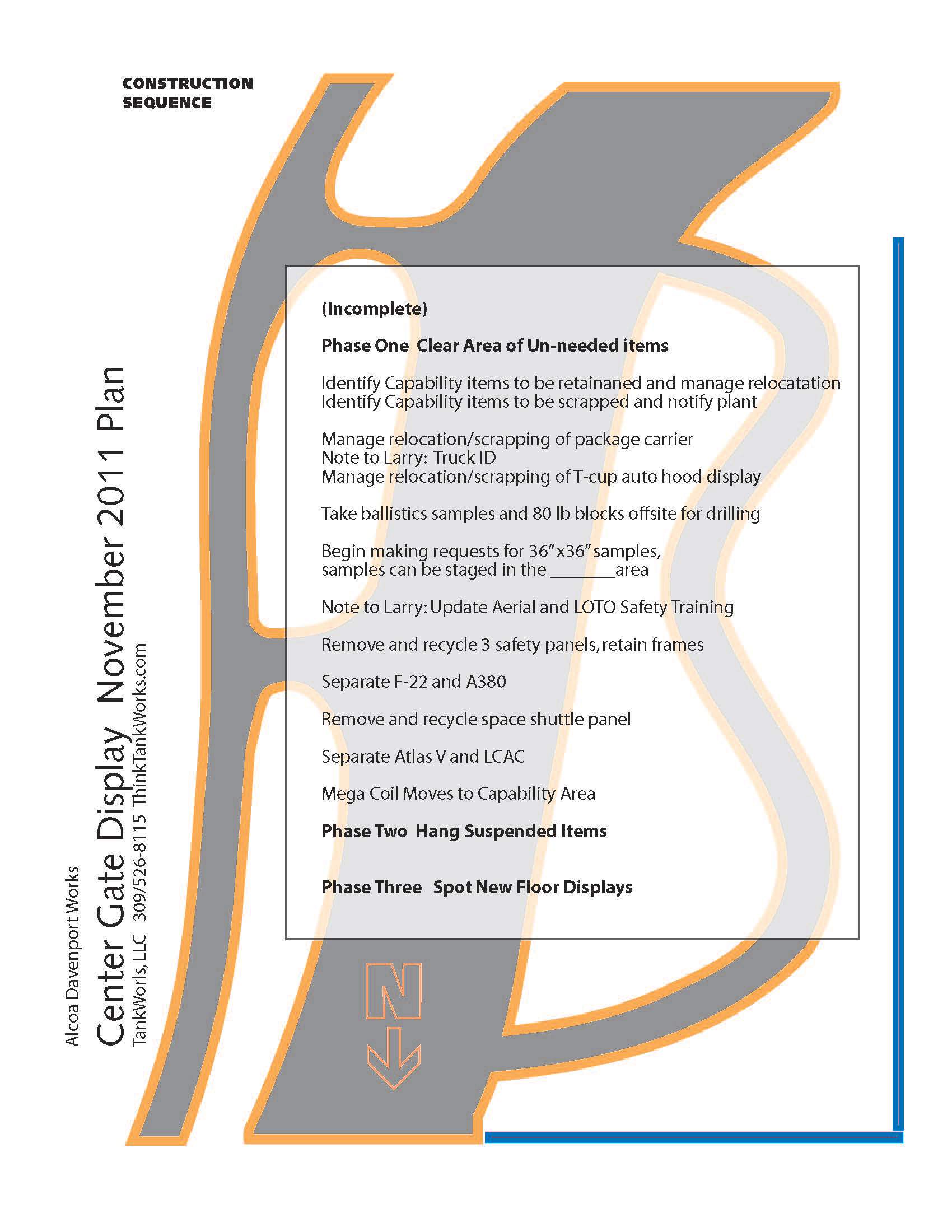

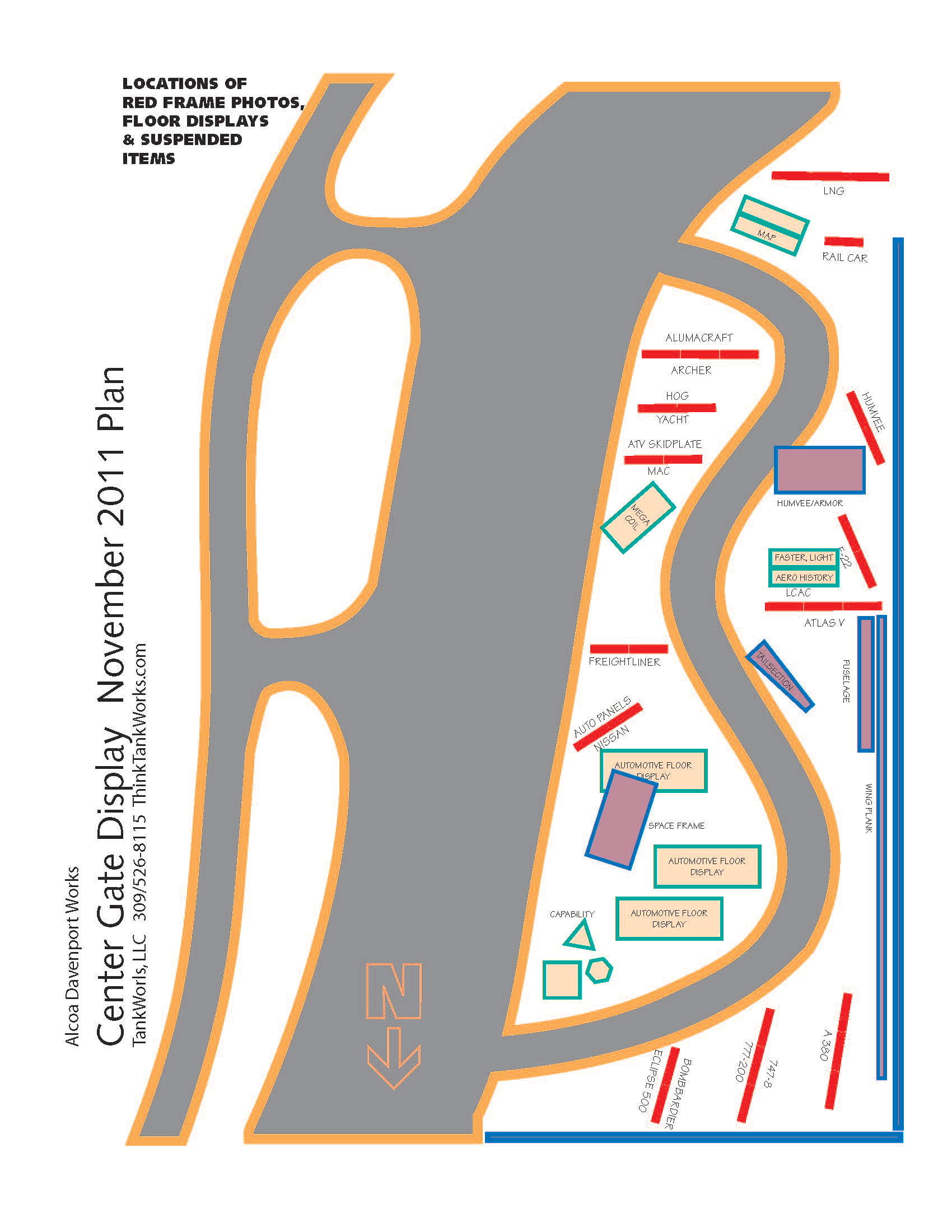

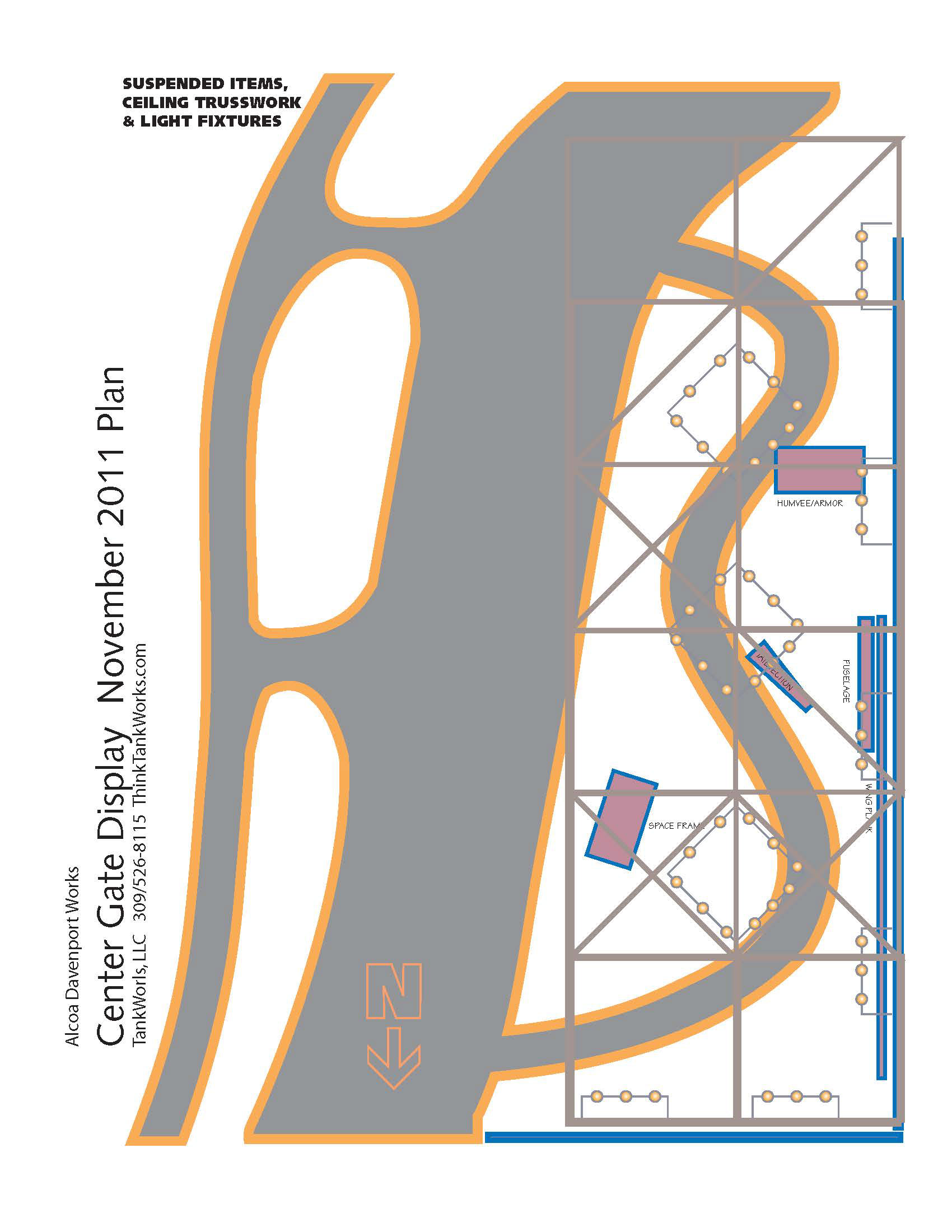

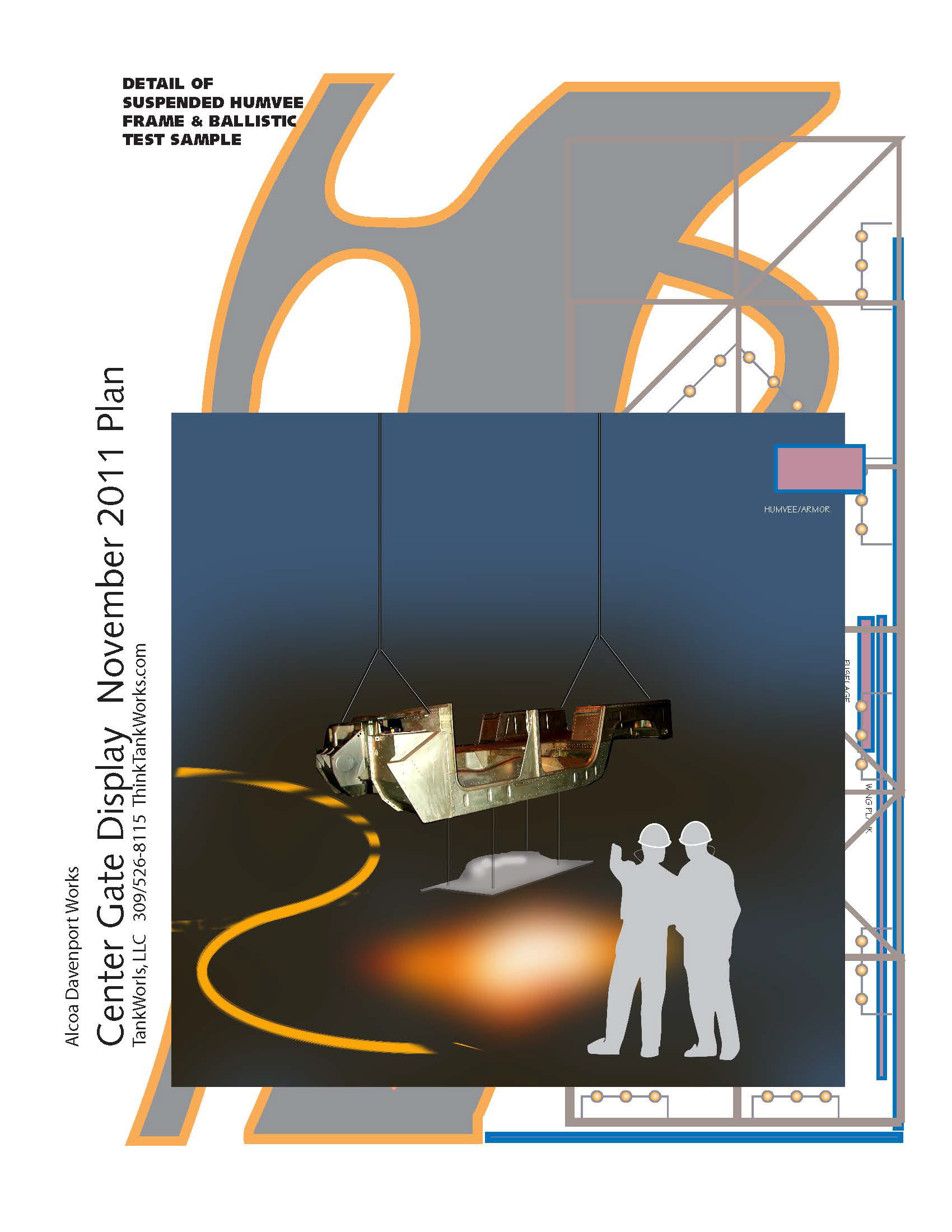

"How long has DavenportWorks been here?" is often the first question a visitor makes when they enter the plant. I chose to answer the question with a 80 x 20 foot infographic, as seen in this early concept sketch. Below, some of the floor plan studies for space allocation, traffic flow, content and lighting.

Companies send messages to their customers to tell them how important they are all the time, this was Alcoa's message and I am a good soldier. Scale was on my side, but there were some specific challenges.

The plant is windy. Over a million pounds of aluminum is hot rolled every day. As that product moves through the plant, escaping heat, combined with the wind from a suddenly opened overhead door can create inside drafts over 15 mph.

Because the plant is windy, it is also dirty. Hot oil steams out giant mills to mix with atmospheric dust and distribute everywhere. A light haze is always in the air.

DavenportWorks is dangerous. Semi-sized forklifts move forty-foot planks, cranes move coils overhead, the metal is beautiful, hot and it cuts. Contractor safety training is required, and a drug test.

The proper call sign/way point for DPW should have been Delta Papa Whiskey, but you're not going to find me saying that on the plant floor.

I utilized mesh banner material to take advantage of the vast space provided.

My assignment was to create a display that would make customers question whether their order was worthy.

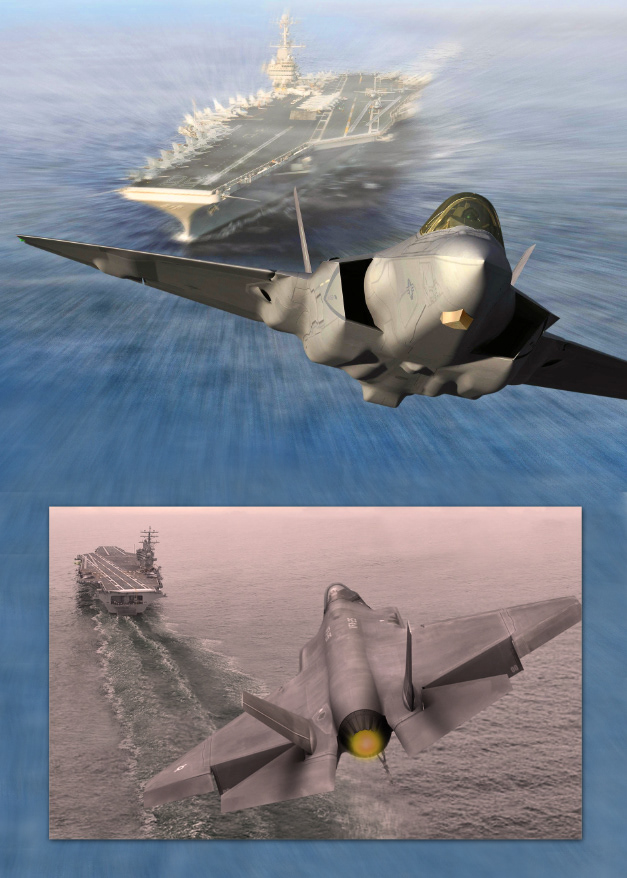

This was my favorite image panel.

This was my favorite image panel.

I specified a muted red, white and blue palate for the walls, colors deliberately selected to mask the grime between cleanings. The painters elected to paint the red color first and I nearly had a plant-wide rebellion until the blue and white were up.

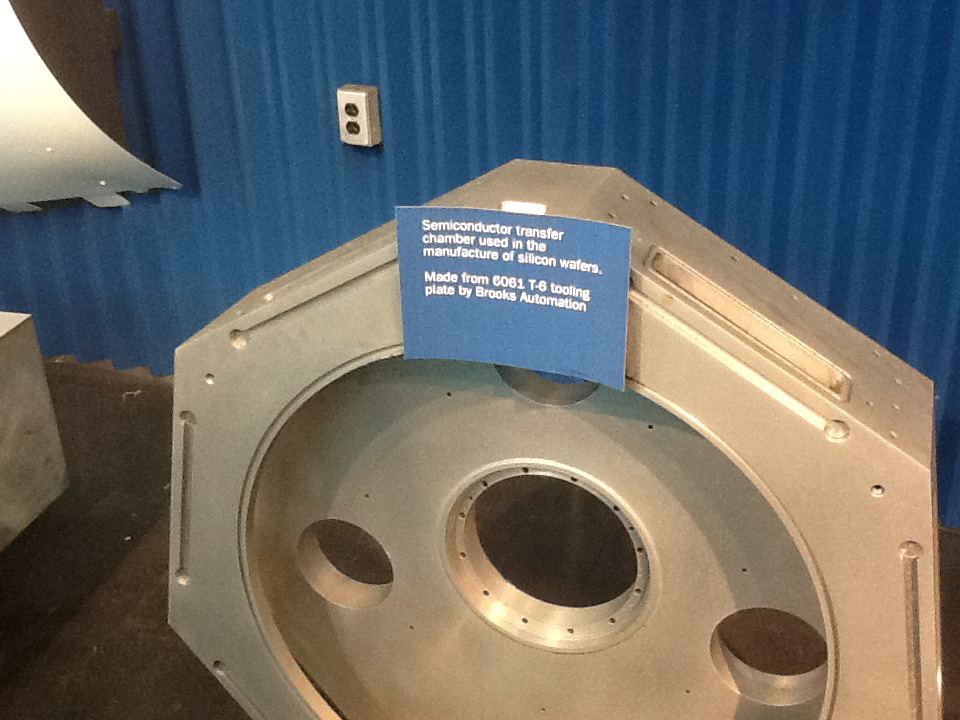

As visitors concluded their tour, they passed this reminder of DavenportWorks capability.